[ad_1]

Enough has been reported about the achievement that catapulted India into an illustrious league of spacefaring nations, but as Isro Chairman S Somanath and M Sankaran, director, UR Rao Satellite Centre, the lead centre for Chandrayaan-3 reiterate, the mission was forged over four years of relentless toil and unwavering commitment by a brigade of Isro scientists and engineers.

TOI ventured into the heart of this celestial odyssey, sitting down with the unsung heroes — a select few from the indomitable 34-member core team including Project Director P Veeramuthuvel and Associate Project Director K Kalpana — who marshalled 500 brilliant minds to take India to Moon.

Their tireless efforts, sleepless nights, and unwavering belief are all part of the tapestry that is Chandrayaan-3.

“It was simple. Failure was not an option,” Veeramuthuvel says. But success didn’t come easily. “…The lander (Vikram) was meticulously crafted to adapt to any descent path it encountered. No room for compromise was left.”

The team developed multiple mission plans and meticulously designed tests that rectified the shortcomings identified in Chandrayaan-2. “All teams, sensor, navigation, guidance and control (NGC) system, propulsion system, and components, worked in unison. They breathed Chandrayaan-3 for four years,” Kalpana says.

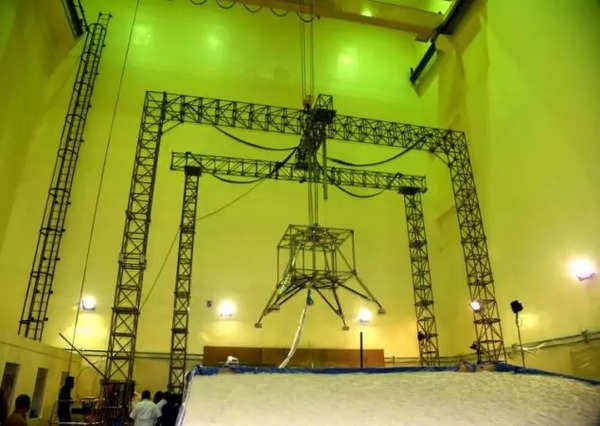

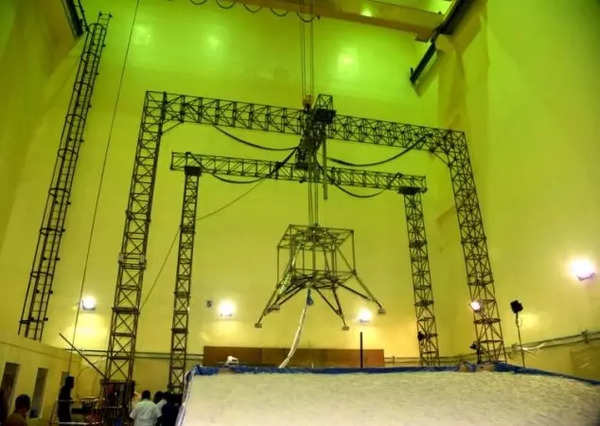

Test site at Sriharikota Chandrayaan-3

Predicting & Overcoming Failure

The confidence on Landing Day wasn’t a result of just commitment and toil. It stemmed from hundreds of lab-level testing and three main test types — Integrated Cold Test (ICT), Integrated Hot Test (IHT) and Drop Tests, each of which included a variety of tests — which predicted every possible failure and ensured every small system overcame it.

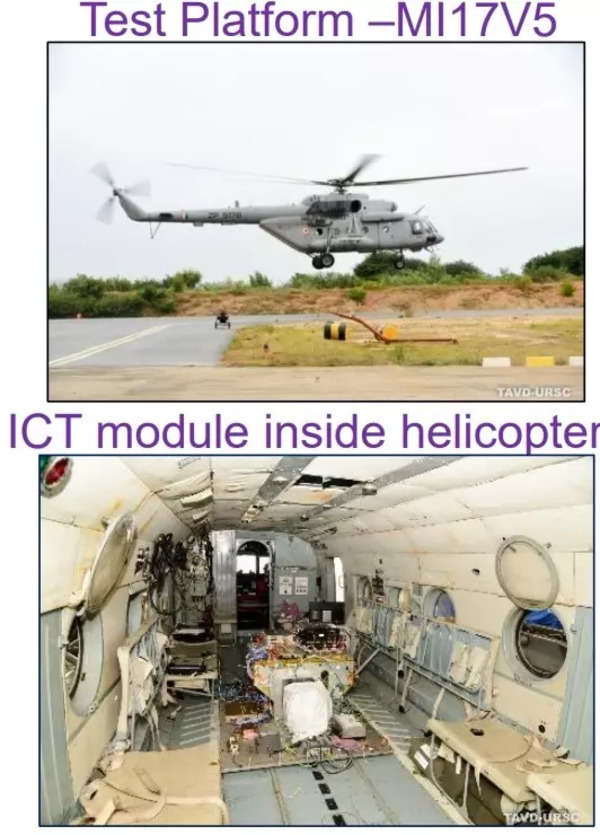

Together, there were more than 80 ICT, IHT and Drop tests. ICT was marked by 25 hours of flight time and 23 rigorous sorties on an IAF helicopter. A wide range of sensor combinations and varied test configurations were tested. Issues that arose were diligently addressed, ensuring reliability.

“In Chandrayaan-2, we used an aeroplane so we couldn’t hover or bring it to low altitudes like 10 metres. It performed flights on a flat bed at a 6km altitude, leading to limited evaluation of system-level sensors. In Chandrayaan-3, the helicopter allowed us to test sensors at different levels of the power descent phase for five months. We even did tests while it hovered at 800m and 150m, just as Vikram did while landing on Moon,” Veeramuthuvel said.

Integrated cold test

Then came IHT in Sriharikota. It included dry runs, static tests, closed-loop evaluations, and truncated de-boost tests with an emphasis on achieving near-equal lunar conditions. While ICT focused primarily on sensors and navigation, IHT featured engine firing in 25 tests.

All this wasn’t enough to ensure Vikram doesn’t topple. This brought the team to Lander leg drop tests, where it gained invaluable insights into crucial aspects of power descent and landing. It juggled these tests simultaneously while creating intricate models, akin to birthing many satellites at once. Lunar craters and boulders created in Chitradurga served as a testbed for helicopter experiments.

“We meticulously assessed integrated sensors and navigation performance, ensuring every system was in sync. Lander leg tests were conducted on lunar soil simulant testbed, rigorously examining a range of conditions, from steep slopes to flat surfaces, hard and soft terrain, and various combinations of horizontal and vertical velocity,” Veeramuthuvel said.

The team built seven models of Vikram, three of which were scaled-down models. “The challenge of simulating this lunar world in our tests was a monumental task,” he added.

Structure on flat bed Chandrayaan

1-lakh Simulations & 25TB Data

Chandrayaan-3 had something Chandrayaan-2 did not: A simulation group. Although the previous project also did simulations, they were not as elaborate and were carried out by the control system teams. For Chandrayaan-3, a new team was formed.

Aditya Rallapalli, project manager (simulations) said: “We have 25TB simulation data from more than 1 lakh tests. That’s the magnitude of simulations!”

Bharath Kumar GV, deputy project director, NGC-simulations, explained: “Testing for nominal conditions wasn’t enough. We predicted various parametres that could go wrong and built models. Then corrections were carried out at each level.”

At the core of simulations were the four testbeds: Six degrees of freedom (6-DOF), Onboard In-loop Simulation (OILS), Software In-loop Simulation (SILS) and Hardware simulations. They each had unique strengths and limitations, but a common objective: Making Vikram soft-land on Moon.

Dry run test at Sriharikota Chandrayaan-3

6-DOF is a digital realm where models and code come to life. While onboard software is absent, these simulations serve as the crucible for validating designs and trajectories with speed and accuracy.

During OILS, both the onboard software and NGC simulations took centre stage but these tests were sparingly executed due to their time-consuming nature. SILS was a comprehensive approach involving digital simulation of onboard software, which Prashanth Kulshreshtha, project manager (software) and team built and tested exhaustively. The onboard software was a critical part of the redesigned lander.

The final testbed was Hardware Simulator where actual flight equivalent hardwares and software was involved.

Drop test facility Chandrayaan-3

Trajectory & Guidance

Madhavraj, project manager (trajectory) and his team member Kuldeep Negi said that his team’s job was to ensure that systems behaved exactly like the 1-lakh simulations showed they would behave.

“Simply put, our job was to see that all the planning on the ground worked. It involved a lot of mathematics,” Negi said.

Every manoeuvre, beginning with the five Earth-bound manoeuvres, then the trans-lunar injection, lunar orbit insertion, five lunar-bound manoeuvres, two deboosts to get into pre-landing orbit had to happen exactly as planned.

“We had a ‘Plan B’ for each of them, but our ‘Plan A’ worked every single time. That’s how successful we were,” Madhavraj said.

Rijesh MP, DPD, NGC controls and dynamics, said: “If I’ve to sum everything up, I’d say: Guidance couldn’t fail!”

To do that Rijesh’s team overcame several challenges, key among which was to ensure guidance systems were in sync with engines. Engines could be slow in acting on a command, the team didn’t want that to be read as an error or deviation, so guidance systems had to understand engines and work with them for a perfect landing.

It was all of this that put India on the Moon and Indians over the Moon!

LUNAR CONQUERORS:

Project Director: P Veeramuthuvel

Associate Project Director: K Kalpana

Deputy Project Directors: Shaik Johny Basha, Baiju Payyappilly, Chayan Dutta, A Rajendra Kumar, Venkata Raghavendra, Motammarri Srikanth, Pramod Kumar Soni, Jaishmi Kiruba Rajathi R, Lakshmi A, Senthil Kumar V, Bharath Kumar GV, Rijesh MP, E Dinakaran, Arun Kumar Gupta, Mallikarjuna, Priyanka Mishra, Senthil Kumar G, Padavala Vijay Ganesh, Ramachandra, Muthulakshmi, Koteshwar Rao C, Chinmay Kumar Rajhans, SN Ram, Anil Kumar, Ajit B, Jogeshwar Rao, Vishnu Patel, Amitabh, Ritesh Kumar Sharma, Bijoy Jacob K and Roopa MV.

+100 project managers and principal investigators

[ad_2]

Source link